What is resistance measured in? Before you answer this question, it is crucial to understand what the term means first. As we grasp a basic knowledge of electricity, we can categorize materials into two groups. Typically, conductors allow current to flow through them much more easily than insulators like plastics and rubber. Nevertheless, insulators can conduct electricity if you can supply a voltage that is large enough.

We can observe this phenomenon in lightning. Although air is an insulator, the build-up of a positive charge in the clouds is large enough to cause current to flow to the negatively charged earth. Accurately determining the ease through which electricity moves through a material, its applications, the possible errors that can arise during measurement and the best way to choose a measuring device is the subject of this article.

What Is Resistance?

Resistance is a measure of the ease through which an electric current flows through a material. As mentioned above, these values can distinguish between conductors and insulators. So, what is resistance measured in?

To find the electrical resistance of a material, you have to connect terminals to its ends. If a potential of one volt can produce a current of one ampere across the terminals, we can conclude that the material has a resistance of one ohm. George Ohm, a German physicist, named this phenomenon when he discovered one of the most fundamental laws of electricity.

Ohm's law defines the relationship between the basic electrical quantities of resistance, current and voltage. In mathematical notation, the rule is written as V = I x R, where V represents the voltage, I symbolizes the current, and R denotes the resistance. Thus, resistance is measured in ohms.

In a nutshell, Ohm's law declares that the current passing through a material between two terminals is directly proportional to the voltage across the same points. This basic principle applies to most, if not all, electrical devices through components called resistors. Additionally, you should consider the numerous methods used in measuring resistance, the plausible errors in measurements and how to find the right measurement tool.

Applications of Resistance

As stated above, when materials have high resistance, electricity struggles to flow through them, losing energy in the process. The lost energy, typically through heat, is used in making incandescent lamps and heating filaments in electrical appliances.

On the other hand, applications of variable resistance are meant to lower the amount of current in a circuit. For example, telecommunication devices, amplifiers, any digital multimeter, oscillators, transistor radios, and television sets, modulators and demodulators use variable resistors.

Moreover, these devices are found inside fuses, cars, motors, generators, switches, connectors, relays and other components. However, the ubiquity of resistors creates a necessity for measuring resistance accurately. Therefore, the method used to measure resistance value determines the level of accuracy you will get.

How to Measure Resistance Values

1. Ammeter-Voltmeter Method

If we can measure the voltage and current flowing through a circuit, we can use Ohm's law to calculate the resistance. The measurement results are good, but this method lacks the practicality essential in more sensitive and frequent applications.

2. Using a Kelvin Double Bridge

If you want to measure resistance between one milli-ohm and one kilo-ohm, the Kelvin Double Bridge method comes in handy. Plus, the technique provides you with a resolution of a micro-ohm. First, however, you need to increase the measurement current to a level that enables enough sensitivity and include a galvanometer to test the condition of the circuit while manually balancing it.

3. A Two-Wire Connection

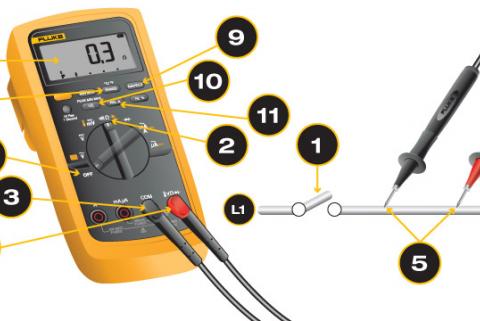

When dealing with resistance values greater than a hundred ohms, a digital multimeter is ideal. The device uses the two-wire method, which forces a current through the test component, measures the voltage at the terminals and calculates the resistance.

The two-wire method does not consider the volts lost across the connection leads since it reads the voltage at the terminals instead of across the tested device. Additionally, the resistance in the lead connection factors into the final results, further skewing the measurement. Consequently, this technique is not suitable if you need to measure resistance accurately.

4. A Four-Wire Connection

The Kelvin method, or using the four-wire connection, is more accurate and consistent when measuring resistance. The technique relies on four different wires where two will be used to supply the current and the rest to deliver the voltage across the test component. Although some current will flow through the current leads and potential leads, the resistance value at these points is small enough to ignore when getting the measurement results.

When using this method, ensure you place the current leads outside the voltage ones, but you have plenty of freedom to choose the placement. Still, the potential leads must be placed across the test component exactly since the final resistance value will be calculated between these points. Plus, you can rely on the four-wire technique for accuracy and consistency when measuring resistance.

Techniques Used in Four Terminal Connection

1. Kelvin Clips

Kelvin clips resemble the more common crocodile clip, except for insulated jaws. Each jaw takes up distinct duties, where one is connected to the current lead and the other the voltage lead. Their size makes them ideal when getting the resistance value in wires, plates and busbars.

2. Duplex Handspikes

Handspikes are small, making them more suitable for measuring resistance across a tiny test component where clips are impractical. Each handspike is made of two sprung spikes, the test leads, inside a handle. One tests the current while the other fosters the voltage connection.

3. Stacked Lead Connection

If your test component is difficult to reach, you may be forced to use a stacked lead connection. Unfortunately, this method may lead to small errors in the resistance value measurement since the connection between the current lead and the potential lead has some non-negligible resistance.

5. Cable Clamps

An essential quality control step when manufacturing cables involves sustaining consistent measurements. If resistance is too low, the manufacturer may be putting too much copper, which is expensive. Alternatively, if there is too much resistance, the ability of the cable to carry electricity will be compromised.

Cable clamps are used to measure resistance in these scenarios. They are placed at the ends of a one-meter test cable to obtain accurate results. Still, the single meter length of the test cable must be exact to ensure resistance measures are consistent across the production line.

6. Jigs and Fixtures

When it comes to rivets, fuses, switch contacts and resistors, jigs and fixtures make the best measurement tools for resistance. The jig holds the component on each test lead to ensure that you get dependable, significant and uniform results when resistance is measured across it. However, jigs and fixtures are bespoke to the testing application.

What Are the Sources of Errors When Measuring Resistance?

1. How High Are the Current Leads?

The length of the lead wire does not affect the results when resistance is measured using a four-terminal method. Generally, the potential lead does not affect the measurement accuracy, but the current leads can significantly alter the readings. For example, if the current leads have high resistance, the voltage across the test component will not be sufficient to get a meaningful result.

2. Is the Connection Clean?

Dirt, oxides and other coatings act as insulators that have high resistance. Therefore, it is critical to ensure that you connect the resistance measuring tool to a cleaned contact point between the test lead and component. Otherwise, the "dirty" connection will cause errors in the readings.

3. Noise in Measurement

Measuring voltage, especially low quantities, generates resistance measurement noise that lowers the accuracy. For example, when two dissimilar metals touch each other in a thermocouple junction, an electromagnetic field is generated through small voltages. The strength of the magnetic field hinges on the type of materials and the temperature difference between them.

This phenomenon occurs in test leads when the field changes or the leads move within it. Therefore, for accurate resistance measurement, it is crucial to eliminate the thermocouple effect by reducing the length of the test leads.

4. Applying the Wrong Current in the Test

Applying a current through a component when testing will affect the device-under-test. For example, if the unit you want to measure has a high-temperature coefficient, a high current will cause it to heat up. You can lower the test current to reduce the chances of heating or send it as a short pulse to improve the resistance measurement accuracy.

5. Fluctuations in Temperature

From conductors to insulators, the resistance of materials depends on their temperature. Therefore, it is vital to control the measurement environment to ensure you can get an accurate read. Plus, this principle applies to measuring the reference standard for the control test. Using temperature probes before each device is tested can help you ensure a consistent ambient temperature in all testing scenarios; otherwise, the resistance values will be different.

How To Select the Right Device for Measuring the Resistance Value

1. The Accuracy

The accuracy of a measuring instrument refers to how close the testing value is to the true one. For example, a resistance measurement device will remain accurate for a specified period and at a particular temperature range. Plus, the accuracy read is denoted as a percentage of the reading with the full-scale percentage.

2. The Resolution

Resolution refers to the tiniest increments that your resistance measuring tool will allow you to read. For example, a digital multimeter capable of offering high resolution will help you read any small difference between each measurement value. However, the accuracy of the device is not a guarantee.

3. Length of the Measurement Scale

A digital multimeter or any other digital device used in measuring resistance has a specific scale length, the number of digits it displays for you to read. If your measurement application requires a higher resolution, you may need to adjust the range. Consequently, longer scale lengths ensure that you do not have to tweak the range for a more accurate resistance value or fit the specific test component.

2. How Does the Device Select Measurement Range?

If the resistance value is unknown, it makes more sense to use a device that will select the measurement range automatically. Admittedly, this tool may mean you will have to wait much longer to get the resistance reading. Plus, using various currents when testing may damage the component being tested.

On the other hand, using a device that allows you to select the range manually can help save time. In addition, this method is suitable when you need a resistance measurement from transformers or motors.

3. Temperature Coefficient of the Instrument

It is crucial to consider the temperature coefficient of the instrument and its test leads as these values can cause fluctuations in the accuracy of the resistance measurement. Ensure the device you get does not alter the measured reading because of falling prey to the whims of changes in ambient temperature.

4. The Mode and Magnitude of the Current Used

As stated above, when you measure resistance, you need to supply a current to the device being tested. If this current is too high, you will read errors in the measurement. Consequently, it helps to select an instrument that can support the right current magnitude when testing.

A prone-to heating component can be measured using a pulse instead of a continuous flow of current. This method will not damage the electric device being tested.

Frequently Asked Questions (FAQs) on Measuring Resistance

1. What is resistance measured in?

Resistance is measured in ohms which is the ratio between current and voltage, according to Ohm's law. This fundamental rule describes the ease through which electricity can flow through a material. If the resistance is high, the component is referred to as an insulator. On the other hand, low resistance means an electric current flows easily, making the material a conductor.

2. How do we measure resistance?

There are four ways of measuring resistance. You can go with the ammeter-voltmeter method, a Kelvin Double Bridge, a two-wire connection or a four-wire connection. These techniques work well in various applications and can offer differing results from resolution to accuracy.

3. What do zero ohms mean?

Observing a reading of zero ohms on your instrument may mean that the resistance value is far below what the device's resolution can show, or the range selected does not suit your application. Admittedly, all materials, even excellent conductors, offer some resistance to the flow of electric current. Thus, there shouldn't be such a thing as zero ohms.

Nevertheless, if your instrument shows you a reading of zero ohms, it may mean there is continuity in the circuit. Since continuity denotes an excellent electrical path, it can help you determine if wires are shorted, whether there is a breakdown in insulation and distinguishing motor terminals.