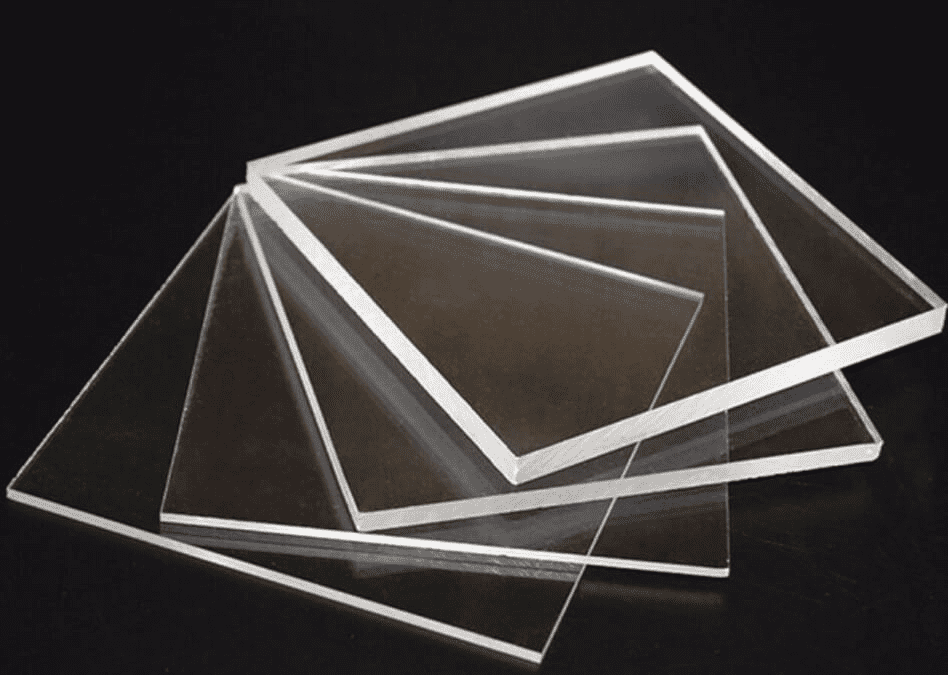

I own most of the cutting tools DIYers have, which come in handy for various tasks. However, if you do not own such implements, do not worry; I will help you find the best tool to cut Plexiglass sheets.

Important disclaimer: Whether using non-power or power tools, you must wear protective gear to protect yourself from any injury.

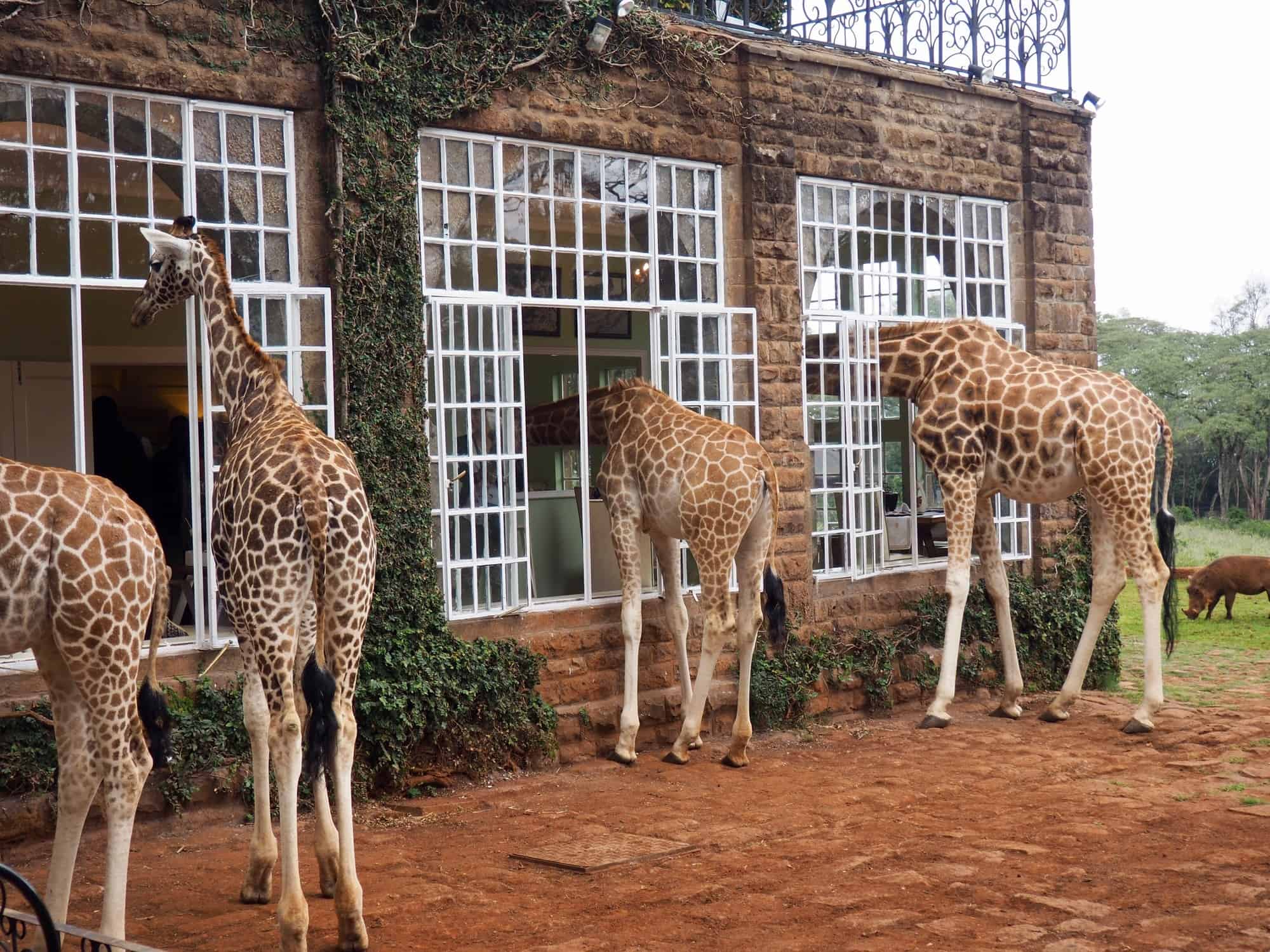

Best Tools to Cut Plexiglass Sheets

Image Source: thespruce.com

Depending on its thickness, I use the following tools to cut through a Plexiglass sheet. I will discuss techniques later in the sections below because having the tools alone is not enough.

- Circular saw

- Sable saw

- Jigsaw blade

- Table saws

- Utility knife

- Glass cutter

- Laser cutter

How to Avoid Cracking the Plexiglass Sheet When Cutting It

Image Source: Arch2O.com

a) Make a Deep Groove When Using the Knife

I have highlighted the utility knife as one of the tools to use when cutting thin Plexiglass sheets. When making grooves on the surface of the Plexiglass sheet, make the cuts along the same line to create deep ones. This ensures the Plexiglass breaks easily when separating the cut parts.

The deep-scored line weakens the Plexiglass sheet for easy breakage, while shallow grooves will not give a clean cut.

b) Use the Correct Blade for the Job

Image Source: tradeinn.com

Avoid using a dull blade because this will lead to an uneven cut along the edges. This article has a section on which blade you should use to cut a Plexiglass sheet.

c) Do Not Remove the Protective Film

When buying Plexiglass, it comes with a protective film that covers it. When cutting the Plexiglass sheet, removing the plastic film covering is tempting. However, I keep this covering on to prevent chipping during the cutting process. The protective film will protect the Plexiglass from scratching on the surface when clamped to the table.

d) The Blade Should Be Cool

While a blade might be able to give a smooth cut, a hot blade will melt the acrylic sheet. This is especially the case when cutting thinner sheets of Plexiglass. An overheated blade will ruin the sheet altogether. To keep the blade cool in a powered tool, I periodically turn off the electric saw blade to prevent heat buildup.

When cutting thin Plexiglass sheets, I use soapy water on the surface of the Plexiglass. Soapy water lubricates thinner Plexiglass sheets for the blade to cut through easily.

Using a sharp blade is another way of ensuring the blade does not overheat when cutting.

e) Cut on a Flat Surface

Cutting Plexiglass sheets on a flat surface will avoid a lot of movements when making cuts. I work on a stable flat surface, especially when cutting a thick Plexiglass sheet.

f) Clamp Down the Plexiglass Sheet

Image Source: amazon.in

When cutting a sheet of Plexiglass, I do not want it to move with the up and down motion of the blade. I use clamps to hold down the acrylic sheet to the work surface. This way, I can cut straight lines with neat edges. I clamp down both the thick and thin sheets of Plexiglass.

Cutting Plexiglass Sheets With a Box Cutter

I do not use a box cutter to cut through thicker Plexiglass sheets. However, the blade can cut through the thin ones. Also, the utility knife is fairly easy to access compared to tools like a circular or electric saw. Therefore, it is always my first go-to when cutting through acrylic sheets.

Image Source: topsknives.com

Using the right technique, you can succeed in cutting straight lines through Plexiglass. Here are the steps I use when cutting Plexiglass with a box cutter.

Step 1: Set Up

Setting up correctly is perhaps the most important step in this process to avoid ending up with uneven cuts on the Plexiglass. So you must wear protective gloves to keep your hands safe from the cutter and a pair of safety glasses to protect your eyes from small chippings.

Place the Plexiglass on a flat work surface and clamp it down to avoid slippage of any kind. Remember, do not remove the protective film.

Step 2: Draw a Line

I never make guesses whenever I am cutting Plexiglass or anything for that matter. Using a permanent marker/grease pencil for Plexiglass, I create straight lines along which I use the blade to cut.

Step 3: Scoring

Scoring means making cuttings along the same line over and over to create a line of weakness. This line is where the glass eventually breaks apart. I make about 15 scoring lines, ensuring I make a deep groove each time I score.

Finally, I turn the Plexiglass on its other side and make similar grooves. Again, I want to ensure the grooves are along the same line.

Step 4: Snap!

Once I have made deep enough grooves on the Plexiglass, I move it to the edge of the table I was working on. I clamp down the glass once again using c-clamps of any other clamp. I break the two parts using a strong downward force to get clean-cut Plexiglass sheets.

This should work if the grooves I made were deep enough. This method works better for a thin sheet of Plexiglass.

Step 5: Sanding

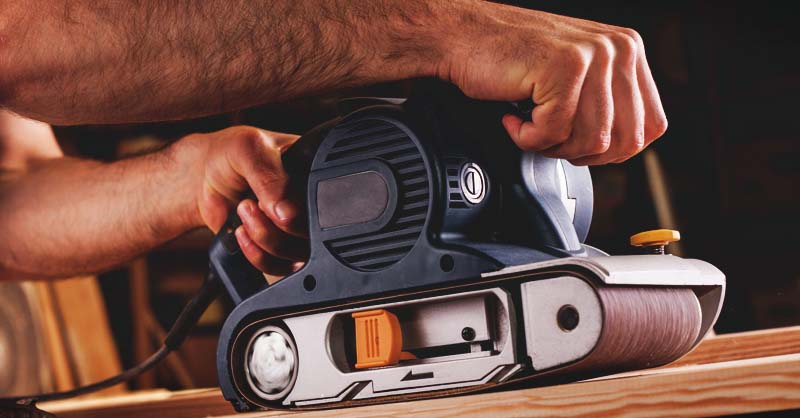

Image Source: morningchores.com

While the surface I have gotten might be smooth enough, I must sand the cut edges using a wood sanding block. I sand gradually from the coarse to fine teeth sandpaper for better results.

Best Blade to Cut Plexiglass

While there are different tools I can use to cut Plexiglass, the quality of the blades on the tools will make the biggest difference during the cutting process. Here is what I look at when searching for blades.

a) Fine Teeth

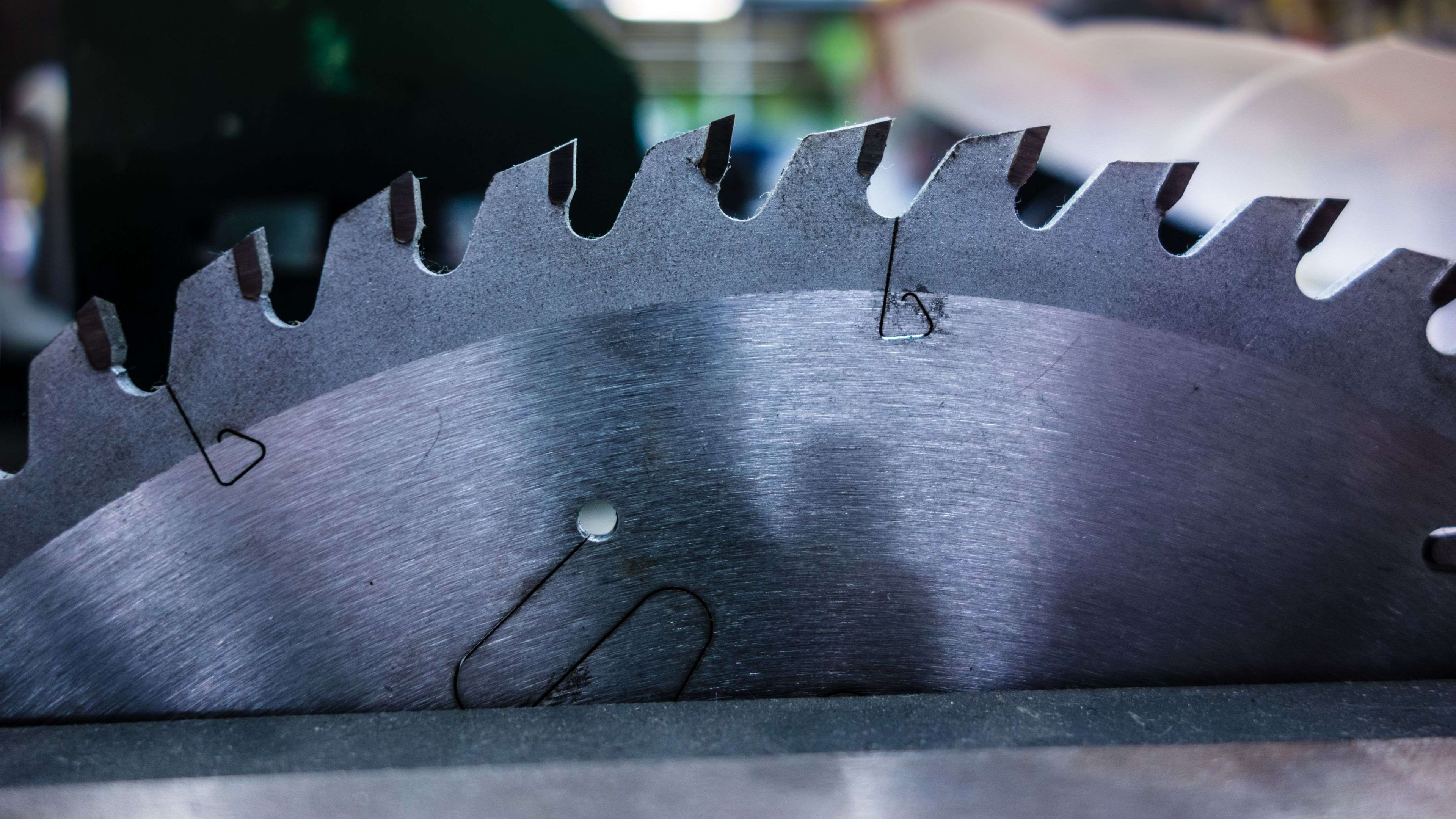

Image Source: manomano.co.uk

If the blade has coarse teeth, the result on the Plexiglass might not be as even as I want it to be. When cutting through thin Plexiglass, a fine-toothed blade of about 10 teeth per inch is vital to use.

b) Acrylic Blade

There is a difference between the iron cutting blade and the acrylic blade. You can use the normal blade if you do not find the acrylic blades, provided it is a carbide-tipped blade.

c) Sharp Blade

When cutting Plexiglass, ensure you use very sharp blades. I never compromise on the sharpness of the blade to help me get over the process neatly with a surface that will be easy to sand.

Image Source: oellasawandtool.com

When using a box cutter, use a new blade.

d) Crosscut Teeth

When using a circular saw, use one with crosscut teeth, as this will give you results without chippings. There are jig saw blade types for Plexiglass as well that you can find in the market.

How to Cut Plexiglass Using a Circular Saw

Image Source: electrogardentools.com

Using circular saws is the fastest way of cutting Plexiglass. Here are the steps to follow when using a circular saw.

Step 1: Check the Blades

Whenever I want an even cut, I have to check if the blades with carbide-tipped teeth are evenly spaced. More teeth equal less debris flying around. Furthermore, I take care of debris using a vacuum debris cleaner.

Step 2: Mark the Plexiglass

I ensure I cut an even line by drawing a straight one on the Plexiglass beforehand. While some cutters have guides to help get a straight line, I still need a drawn line to guide me for accuracy.

Step 3: Start the Saw

I have to ensure the saw is running at its full speed before starting to cut the Plexiglass. A slow blade will leave a rough surface behind because it is not strong enough. Additionally, I push the Plexiglass against the blade for smoother results.

What About Curved Cuts?

Some interior design ideas involve curved cuts, and I am able to get those done well too. So how do I go about the curved lines?

First, I use all the preliminary steps I use on the circular saw but on a jig saw. A jig saw will work best compared to circular or table saws because you can use it more easily.

Once I have drawn out the shapes, I drill holes in sections with corners. This is so that whenever I cut, the blade does not bend when it gets to the curve. The holes allow the blade to make a curve without bending.

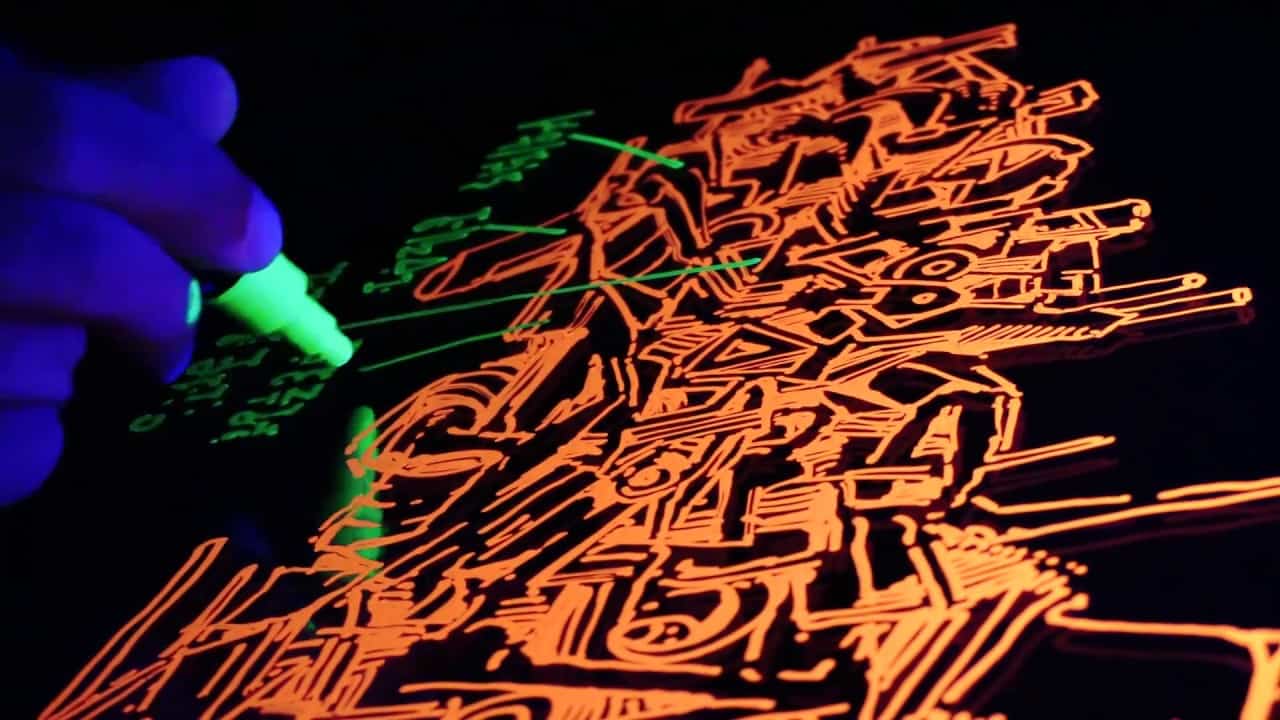

Cutting Plexiglass Using Laser

Laser machines are popular tools for cutting Plexiglass. Therefore, I recommend using laser cutters for clean cuts. In addition, lasers will come in handy whenever I am producing on a large scale because they work fast.

Once I learned how to use a laser cutter, my projects have become more enjoyable. Here are the steps I use when cutting Plexiglass using a laser.

Step 1: Check the Wattage on the Laser Cutter

Different Plexiglass sheets have varying thicknesses; therefore, I use appropriate wattages on the laser cutter when cutting the acrylic. For example, I use about 150 watts for thin glass and up to 400 watts for thick ones.

Step 2: Clean Lens

The laser machine uses a lens to focus the laser. So, a dirty lens will lead to an uneven cut. I avoid ruining perfectly good Plexiglass by always cleaning the vital part. A dirty lens will not focus the laser properly, so it is vital to know how to clean a laser cutter lens.

Step 3: Focus

When I want to achieve a clean cut on the Plexiglass, I focus the laser on the surface of the glass using the lens. Have you ever used a hand lens against the sun? If the rays are spread out, they will not achieve much. The concept is pretty much the same for laser cutting machines.

Whenever I am making a cut on a thick sheet of Plexiglass, I focus the laser somewhere in the middle of the glass. If I focus the laser only on the surface of the glass, the intensity will reduce as it goes lower into the cross-section of the glass.

Cutting Plexiglass Using a Glass Cutter

Image Source: lowes.com

Using a glass cutter on Plexiglass is similar to using a utility knife. For this reason, I choose to work with a glass cutter when cutting a thin Plexiglass sheet. In addition, a glass cutter might be a bit better to handle than a box cutter because it is suited more for cutting glass.

Final Thoughts

You can do a lot of projects using Plexiglass once you know how to cut the material properly. You will not go wrong when cutting through acrylic glass with the tools we have outlined above.