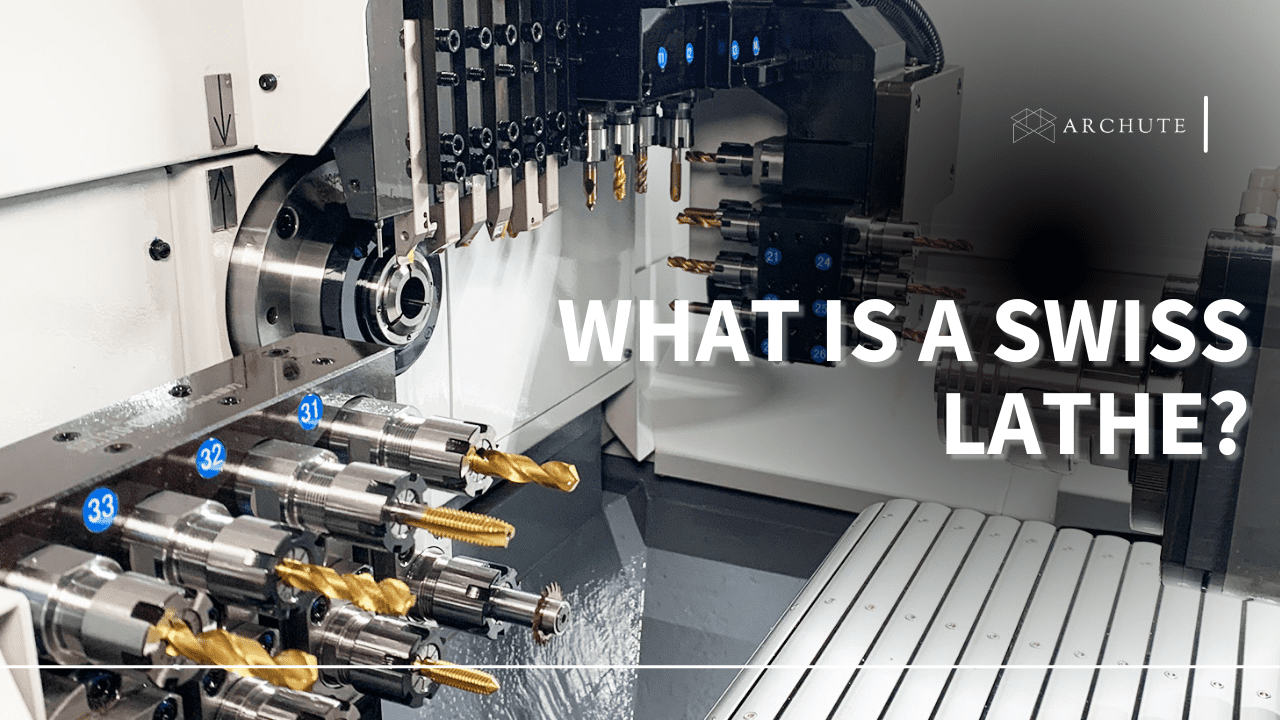

CNC machines have spread across different industries, and their applications are getting more by the day. However, the Swiss-type lathe seems to be picking up more in different fields than other lathes. The Swiss machine lathe is picking up because of its turning mechanism, which is more accurate and appropriate in different fields like medicine and electronics industries. So, what is a Swiss lathe?

What is a Lathe?

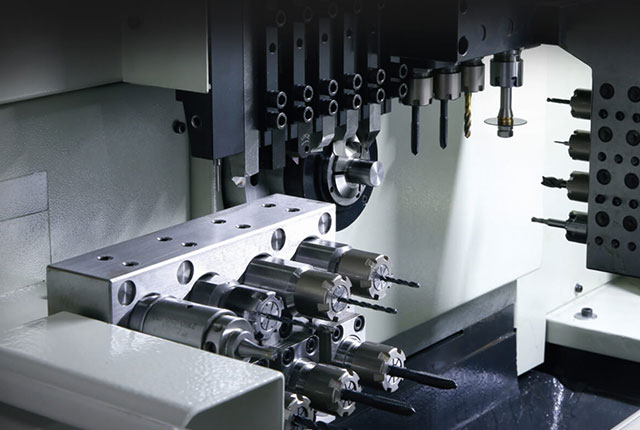

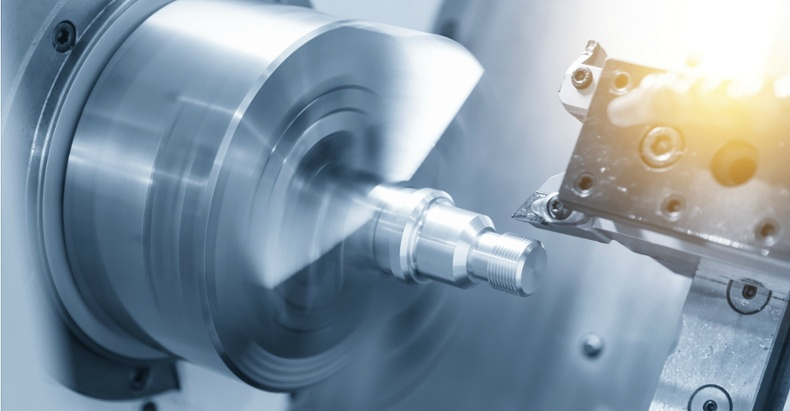

A lathe is a machine for shaping materials like wood, metals, plastic, and more. The lathe specifically does the job of turning the material being cut against the blades doing the cutting. So instead of the blade moving, the turning machine does all the work. Conventional lathes rotate about an axis that is attached to a CNC machine.

Image Source: cncwmt.com

The CNC lathes do more than rotate the material for cutting. A conventional lathe can hold material for sanding, drilling, deformation, facing, turning, or knurling. The reason why one would need a lathe is to create symmetry in the material. The lathe ensures the material turns on an axis, making the action on the material even on all sides.

What is a Swiss Lathe?

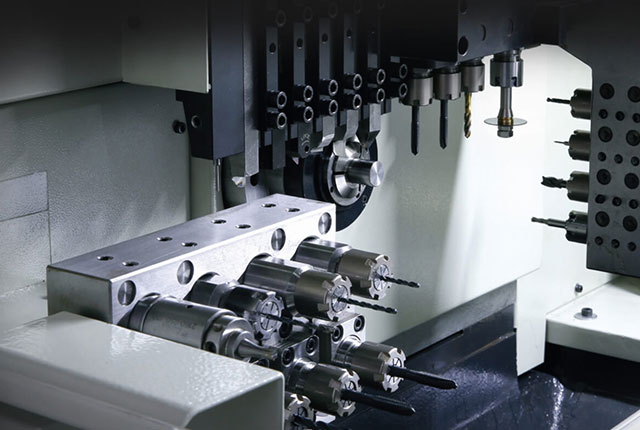

The Swiss-type lathe is unique in how it operates by allowing the material to move while the tools stay stationary on the z-axis. The other thing that makes Swiss-type lathes unique is the inclusion of the collet, which further holds the object in place for more accuracy.

Image Source: winnmachine.com

The Swiss machine appeared not long after the invention of the collet, which seems to have inspired the inventor. The collet on Swiss-style lathes is revolutionary because they allow for manufacturing small, intricate parts. In addition, the material being cut no longer depends on the bar stock for all the support. Swiss turning machines are thereby by far more accurate than other traditional lathes.

The invention of the collet not only revolutionized CNC lathes but also added a lot of advantages to what Swiss machining can do. Here are some of the benefits of the Swiss-style lathe.

Benefits of the Swiss Lathes

Image Source: cncwmt.com

1) Several Operations

While the traditional lathe performs only one operation during the machining process, the swiss lathe can perform multiple operations simultaneously. The Swiss automatic lathes perform many operations at once and can do so in different zones on the material being turned.

As a designer, I need a fast and efficient laptop that helps me design and come up with ideas. However, my firm needs a CNC machine that will give me the outcome just as fast.

2) Faster Operation

Swiss CNC machining allows for a more increased production rate since it can work on different zones of material simultaneously, unlike traditional lathes. Therefore, Swiss-type machines make production multiple times faster than traditional lathes, which can only perform one specific function at a time.

3) Multiple Materials

The accuracy that comes with the Swiss-style lathe opens up an opportunity to work with more materials that can be used to make a lot of products. Some materials include aluminum, carbon, brass, steel, nickel, plastics, nylon, titanium, and more. Furthermore, swiss machines are more accurate and will make good use of those materials.

4) Accurate

While there is 3-D printing to achieve accurate outcomes, Swiss CNC machining still comes on top. The guide bushing revolutionized the number of actions the CNC Swiss-type machine can perform. The guide bushing ensures the material being worked on does not move from side to side, keeping it centered and allowing for precision machining. In addition, Swiss turning centers include a moving head, which can be computer controlled to make extremely precise parts from the materials.

To show just how accurate and efficient the swiss lathes are, watchmaking companies used them extensively before the current generation computers were even a thing. The Swiss watchmaking industry was developed in the 19th century. That was long ago, and the machines could operate at clinical levels. Imagine what machines can achieve today and what great watches can be made out of the machine.

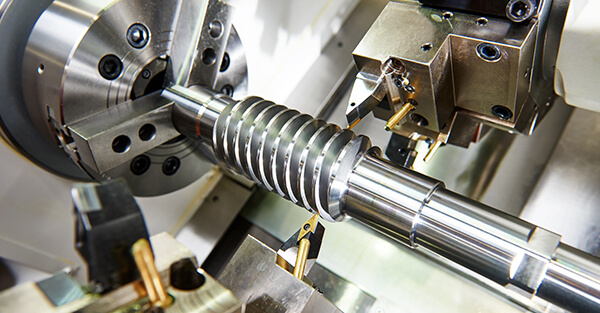

Some Downsides of a Swiss Lathe

Image Source: owensind.com

While the advantages are unreplaceable, the machine has some downsides to it. Here are some of the disadvantages that come with the swiss type lathe.

-

- The machine is a bit pricey compared to other machines.

- The swiss type lathe requires a lot of maintenance.

- Only highly skilled labor is required to operate the machine, unlike the conventional CNC lathes.

- CNC swiss type machining mostly focuses on cylindrical objects.

- The machines work better with light materials.

While there are downsides to Swiss machine cutting, the advantages outweigh the disadvantages by a significant margin.

Differences Between the CNC Swiss Type Lathe and Conventional Lathes

Image Source: inversesolutionsinc.com

a) Headstock

A conventional CNC turning lathe has a fixed headstock, while the Swiss machining process uses a moving headstock. The moving headstock allows for multiple operations and the processing of complex parts compared to a fixed headstock.

b) Coolant Liquid

The Swiss turning machine uses oil as a coolant, while other machines use water as a coolant.

c) Programming

Programming the Swiss-type lathe is opposite to programming a normal lathe. This is because a positive offset is used during Swiss machining, while a negative offset is used on the traditional lathe. The z-axis offsets are something that became popular with the swiss lathes.

d) Guide Bushing

The conventional lathes hold the material on the spindle. This means that a long material is bound to vibrate more, reducing the accuracy. In addition, only the portion held will be stable, which is not ideal when the cutting tool needs to produce precise parts.

e) High Volume Production

Swiss machining allows for high-level production because of the tight tolerances assured by the collet chuck. The bar stock material also turns rapidly to increase the action rate of the material. Swiss machining leads to the rapid production of precise parts of items such as bullets, which need very precise parts.

Secondary operations also allow the machine to do the work of more than one machine with high precision. As a result, the cycle time is shorter, which means more parts can go into the machine.

f) Machining Small Parts

One of the key benefits of the Swiss lathes is the ability to machine to work on extremely small parts like watch components. However, complex components are vital in some items, and accuracy can be maintained.

Final Thoughts

Image Source: techdee.com

Swiss lathes revolutionized industrialization back in the 1800s. However, the efficiency it brings to the table is a reason why the technology is still here with us and is still thriving.